Velum Protective Filters

Velum Filters | Velum Air | Velum XL | Velum Motor | Velum Smart

Prevent dust and oily mist from clogging internal filters, reduce downtime, and cut maintenance costs

with Velum’s easy-to-replace external filter system.

Contact Your Local Morris South Expert

Email: pmgroup@morrissouth.com

Charlotte:

8530 Steele Creek Place Drive, Suite H, Charlotte, NC 28273

Bartlett:

3121 Bartlett Corporate Drive, Bartlett, TN 38133

Huntsville:

3611 Jack Kendall Way, Huntsville, AL 35806

Frequently Asked Questions

1. Can Velum filters be used in any machine?

Yes! Velum is compatible with CNC machines, compressors, electric motors, cooling systems, and more.

2. How do Velum filters work?

Velum filters are applied externally to the machine ventilation and cooling system's entrance grid. It's a patented-knitted fabric to capture dust and oily mist before they reach the inner filter, allowing fresh air to pass through while protecting machine components.

3. How often do Velum filters need to be replaced?

The recommended replacement frequency is once a week but this can depend on the working environment and dust levels. Velum filters allow for visual inspection, so you can easily determine when a change is needed. The replacement process takes only 5 seconds, requiring no additional work.

4. What is the difference between Velum, Velum AIR, Velum XL, and Velum MOTOR?

- Velum: General-purpose filter for automation, cooling, and production processes.

- Velum AIR: Denser fabric for compressors, cooling systems, and heat exchangers, preventing overheating.

- Velum XL: Designed for large industrial machines, offering better airflow and protection for heavy-duty applications.

- Velum MOTOR: Protects electric motors with a reusable polypropylene holder and a polyester filter, available with either a magnet or O-ring attachment.

5. How does Velum compare to other intake filters?

Other filters clog quickly, restrict airflow, and require frequent deep cleaning. Velum ensures easy, quick visual checks and fast replacement without stopping production.

6. What are the benefits of Velum SMART?

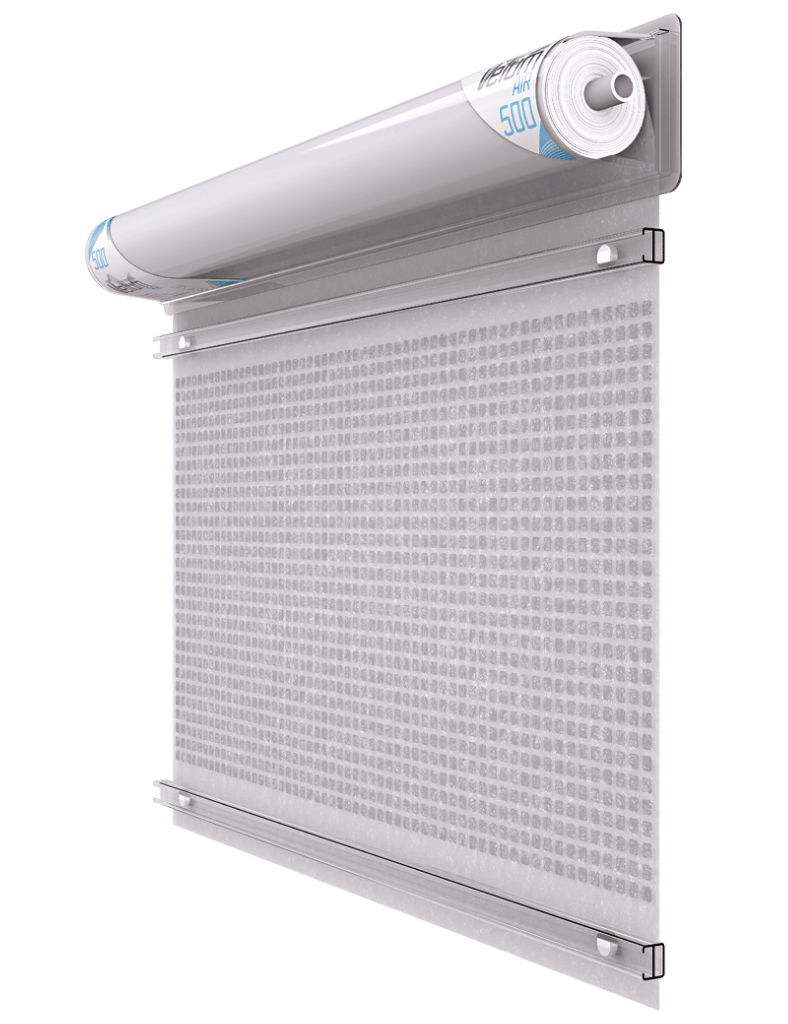

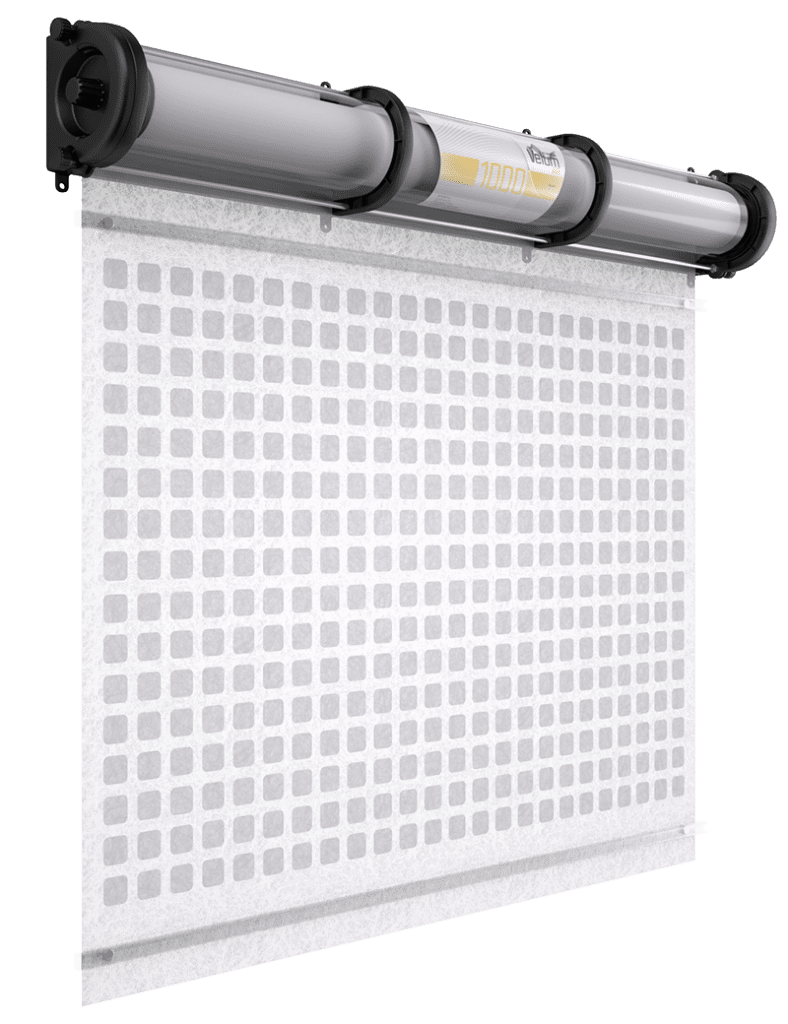

Velum SMART automates the installation and replacement of Velum and Velum AIR filters, reducing filter changes from weekly to just once a year. It’s available in both manual and fully automatic versions, with remote control options via an Android and iOS app.

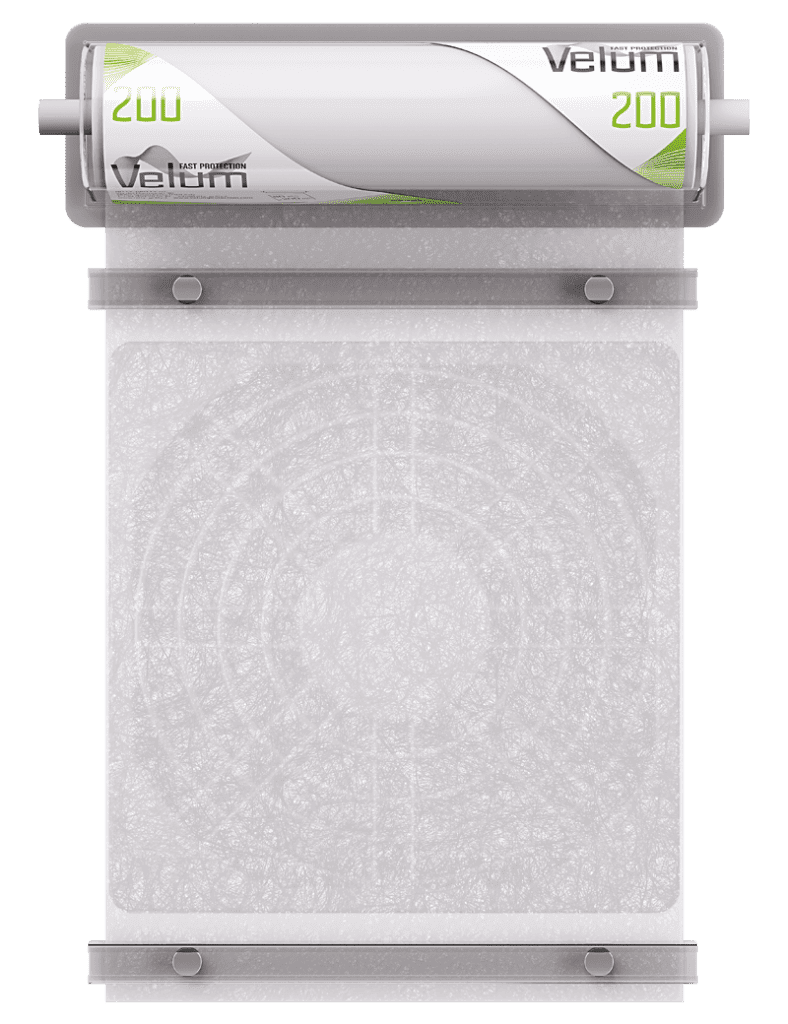

Velum

- Ideal for: CNC machines, automation systems, cooling & production equipment.

- Key Benefit: Best for maintaining machine efficiency with easy weekly replacements.

- Sheet Amount: 110 sheets (8 inches each)

- Available Sizes:

- 8" (200mm)

- 12" (300mm)

- 16" (400mm)

- 20" (500mm)

- 24" (600mm)

- Refill Sold Separately

Velum SMART

- Ideal for: High-usage industrial setups needing automated maintenance.

- Key Benefit: Automated scrolling system—replace once a year, not weekly!

- Available Diameter Sizes:

- 8" (200mm)

- 12" (300mm)

- 16" (400mm)

- 20" (500mm)

- 24" (600mm)

- Refill Sold Separately